The History of Research and Development

AromaLoc™ was invented in October, 2012 when Dr. Dick Jones, a retired pulmonary research scientist, began making wine from grapes he grew in the Okanagan area of British Columbia. He called his small vineyard “Sweetspot” because of the beautiful setting of steep hillsides and the serious waterfall visible only from his house. He planted his vineyard on the steep hillside facing the waterfall. His background in lung gas exchange equipped him to react to a problem he noticed during his first year of making wine from his own grapes. He noticed nice aromas coming out of a tank of Pinot Gris during fermentation and he immediately thought of ways to prevent, what he later learned was called CO2-induced aroma stripping, and keep the aromas in the finished wine. After a literature search he was surprised that no one had tried to solve this 8,000 year-old problem using the method he had in mind. A special membrane would be required.

Since winemaking happens only once per year he needed to do something immediately to see if his method to preserve aroma made any difference to that Pinot Gris that was already near peak fermentation. Searching through the things kept when he retired he found a container of soda lime once used in his research lab. Soda lime is a granular material that absorbs CO2. He quickly set up a tiny study and used only about 1 liter of the fermenting Pinot Gris. He let the headspace gas flow through the soda lime to remove some of the CO2 and returned what was left to the headspace above the 1 liter sample. After fermentation was complete, he got only one bottle of the experimental wine which was compared to the larger volume that was left untreated. A local wine expert blindly sampled the two wines and confirmed Dick’s impression that the experimental wine had significantly higher aromatics.

After an exhaustive hunt Dick managed to find a new membrane technology that he felt would work for his idea. He contacted the inventors of the membrane and convinced them to supply some samples for testing this novel use.

Over the following winter Dick continued researching aroma preservation techniques and conducting experimental trials. His idea was novel so he embarked on the demanding patent application process.

On receiving the sample membranes he worked with Paul Gardner, a commercial winery owner, to build a membrane housing and prepare for the 2013 winemaking season. Using his invention on white and rosé wines would be straight forward but red wine fermentations posed challenges due to the need for cap management while still keeping the headspace gas tight. Solutions were developed and more was learned. As with any testing, as questions were answered others were created. Unfortunately, the 2013 winemaking season was a bust as the membranes froze during shipping making them useless.

Not daunted, in 2014 Dick flew overseas and personally brought back four membrane sheets and constructed the two units shown in this photo. These membranes were used during many trial experiments to test the theory that concentrating aroma in the headspace could reliably translate into retention of aroma in the finished wine. Without exception, the experiments were successful so it was time to test larger wine volumes.

In 2015 two hollow fiber membrane modules were received. This configuration allowed for a large membrane surface area in a small footprint thus they could handle larger CO2 volumes from larger fermentation volumes. In that year the first experiment on a small commercial-size fermentation was conducted using side by side 700 liter volumes of Pinot Gris.

The protocol for all trials is to have a large tank of wine or must which is ready for fermentation. Any adjustments are made to this entire volume and it is inoculated with the desired yeast. It is then mixed and racked into two identical tanks which are fermented with the same parameters. One of the tanks is fitted with the prototype invention (experimental) and the other is allowed to vent CO2 in the conventional manner (control). Many trials were subsequently carried out with this configuration and these two membranes.

Results from a Pinot Gris 2015 trial can be seen below. This tasting, like all others, was carried out by a tasting panel comprised of accredited industry professionals.

The control and experimental results are presented in two different ways to make visualization easier. The spider graph (figure 1) compares the experimental wine (red line) to the control wine (blue line) and is expressed as the percent change from control. On the bar graph (figure 2) the control is represented by zero on the graph. When AromaLoc™ treated wine scored higher than control the bar is greater than zero. It is clear that for all seven attributes tested, the AromaLoc™ treated wine scored higher, especially for aroma and overall rating.

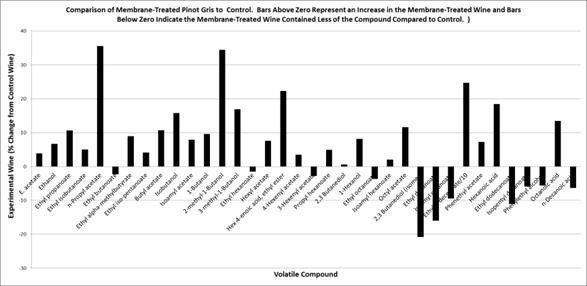

These same wines were sent to the Wine Research Centre at the University of British Columbia for Gas Chromatography/Mass Spectrometry analysis of the levels of individual aroma compounds. Figure 3 shows that most of the volatile aroma compounds were higher in the membrane-treated wine (bars above zero) which was consistent with the blind tasting findings.

The results for the 2015 experiment lead to the design of a machine around the process used at the time and the company “AromaLoc™” was legally formed in 2016. A workshop was obtained and 10 machines were constructed that could handle up to several thousand liters of fermenting wine. These machines were constructed to be commercially viable.

The photo on the left shows the first machine in operation at a large commercial brewery. This configuration worked very well but blind tastings on 2016 wines revealed that despite noticeable increases in the retained aromas there was a slight bitter aftertaste picked up by some tasters. To get answers, various analyses of individual aroma compounds from previous experiments were reviewed and it was discovered that although many of the fruity esters were augmented in the AromaLoc™ treated wine, so were the fusel alcohols.

Having succeeded in achieving aroma preservation, the issue of fusel alcohol retention presented a new problem which needed to be solved, without affecting retention of the beneficial aromas. It took a redesign of the machine to achieve this. Small-scale prototype machines were tested on wine kits and beer during the summer of 2017 and on local grapes in the fall of 2017. The results confirmed that the modifications were successful in enhancing desirable aromas and eliminating the bitter aftertaste.

Larger AromaLoc™ machines were tested in the fall of 2017 with positive results and additional knowledge being acquired to how best use the technology. In 2018 a collaboration opportunity with an ultra-premium winery in the Napa Valley presented itself and it was decided to go outside the partners wine region and get independent evaluation of the AromaLoc™ technology. There were two challenges in this trial. First, a red wine was going to be fermented which presented the challenge of designing a punch down tool that could maintain the gas-tight headspace. Second the fermentations were being done in wooden barrels so a gas-tight seal was also needed. TN Coopers worked with AromaLoc™ and came up with a solution to both of these issues. AromaLoc™ built a machine capable of treating 4 barrels simultaneously. The 2018 trial on Cabernet Sauvignon convinced the winery to continue with another trial in 2019. For the 2019 trial, TN coopers refined the barrel head and punch down system and now have it available as a commercial unit for use with AromaLoc™. Wine Business Monthly Article

Local 2018 trials in the Okanagan valley were also a success on fermentation volumes ranging from 18 liters to 2200 liters.

Pete Desai, with a background in research, product development and commercial / business strategy joined the company in 2019. He will help in developing the commercial launch of the AromaLoc™ 5000. The AromaLoc team is now positioned to capitalize on the synergy of the four partners to fast track commercialization of this unique patented invention.

The AromaLoc™ process has been developed and extensively tested over the last 8 years.

Data from an October, 2019 trial is shown below.

This graph shows the change in each measured aroma compound in AromaLoc™ treated Pinot Blanc compared to identical compounds in the control wine. This is plotted against the hydrophobicity of each compound (logP). Low values for logP are typical for fusel alcohols (red points). The more hydrophobic fruity esters (blue points) are represented by higher logP values. Generally, the red points did not change or decreased while many of the blue points representing the esters increased with AromaLoc™ treatment. The results are interesting because there is a linear relationship between logP and the % change with AromaLoc™ treatment. This is exactly what AromaLoc™ was meant to achieve. The increases with AromaLoc™ are greater for the hydrophobic esters and less or non-existent for the fusel alcohols. This translates into an aroma profile favoring fruity notes without a bitter alcoholic taste.

Commercially Available

Late in 2019 a commercial machine was designed following rigorous testing of prototype units and AromaLoc™ started retail sales worldwide. The commercially available AromaLoc™ 5000 machine is shown at the left.

The Future

Wine

AromaLoc™ is currently seeking collaborations from commercial wine producers in the southern hemisphere to expand on our recent trials using the AromaLoc™ 5000 machine. There are also several bench studies being conducted now and in the future to capitalize on a new aroma analytical testing facility in Penticton.

AromaLoc™ is a research-intensive company that relies on data to make any claims. Although, all analyses of aroma compounds done thus far have shown increased fruity esters in AromaLoc™ treated wine, almost 10% of wine tastings showed little difference between control and AromaLoc™ treatment. However, all tastings have been done within 6 months of fermenting the wine. Dr. J. R. Mouret, a notable wine aroma researcher in France, is convinced that if a wine goes into the bottle with higher concentrations of aroma compounds, it will have more noticeable aroma after storage compared to wine that was less aromatic at bottling. 1 This is because aromas are lost due to hydrolysis during storage. In a wine bottled with low aroma concentration hydrolysis can soon bring these below our odor perception threshold. We regularly go back and re-evaluate previous experimental wines and this seems to support the above principle.

1 LWT – Food Science and Technology. 49(2): 238-244, 2012

Beer/Cider

In the Okanagan valley a trail has been arranged with Cannery Brewing to use the AromaLoc™ 5000 on a range of their production beers. The results so far with beer have been very encouraging with both aroma and mouthfeel improvements noted without dry hopping. AromaLoc™ is very interested in whether this can lead to fewer hops additions for the same hops intensity. If this can be achieved it would lead to cost savings for both hops and perhaps other flavoring ingredients.

To date only one commercial size AromaLoc™ trial with cider has been done, which had positive results. To further the knowledge about the benefits of using AromaLoc™ on cider, a suitable cider producer is sought for further trials.

All Beverages

AromaLoc™ is actively conducting trails to further our understanding of the best method of apply this novel patented invention for preserving fermentation aromas. If your organization is interested in collaborating and seeing first-hand how our technology can improve your product please contact AromaLoc™.