The History

Humans have made fermented beverages for about 8,000 years and have always strived to improve the process. Over that time the fermentation vessels, fermentation practices and raw materials have all benefited from the increased scientific capability of the modern world. Today’s winemakers have at their disposal a wide range of commercial products to aid the fermentation process. Nutrients and other additives have been developed to help yeast produce desirable aromas.

One area during the most critical phase of fermentation has not been solved until now. Our AromaLoc™ system – retains aromas in fermenting beverages. During fermentation, aromas are stripped by the produced CO2. If you can smell aromas, they have forever left the developing product, and none of the advances mentioned above can bring them back. The aroma concentrations that can make wine so desirable exist at microgram per liter or lower levels so they are easily depleted.

The AromaLoc™ Solution

AromaLoc™ has invented and patented a method to solve this problem. These lost aromas can now be retained in the finished product. The system is a totally additive-free and a hands-off process which prevents aromas from leaving the wine, without tampering with the wine or interfering with the fermentation process. We manipulate only the headspace composition above the juice and this translates into changes in the fermenting liquid below. The AromaLoc™ process does NOT capture the aroma and then return it to the beverage after fermentation.

The AromaLoc™ system was conceived in 2012, and over the last eight years dozens of trials have been conducted. We have developed the AromaLocTM 5000 machine to be durable and simple to use. AromaLocTM 5000 cannot accumulate more aroma than is produced so there is no danger of aroma overload. Undesirable aroma compounds are not preserved because they have chemical properties making them flow right past our membrane system and out to the atmosphere. Some ethanol and fusel alcohols are also discarded. Our patented technology reliably enhances the organoleptic properties of wine. Even if your wine is good now, AromaLoc™ will make it better.

Most winemakers think a cold fermentation is required to produce an aromatic wine because it is generally thought that more aromas are produced during cold fermentation. Cool fermentations take longer to complete, are harder to control, expensive to cool and tie up both your resources and tank space. While this can lead to some aromas being retained, there is evidence that warmer fermentations actually produce more aromas. The problem with conventional warmer fermentations is that the rate of CO2 production is high and this strips the aroma faster. Plus, warmer liquids do not retain dissolved aromas in the same concentration as cold liquids. We are conducting white wine trials at 20-25C temperatures and are finding that AromaLoc™ can preserve these previously lost aromas and make a superior product while shortening the fermentation.

We are actively pursuing this research because of the obvious benefits to the wine producer and the consumer.

The best time to operate AromaLoc™ 5000 is of great interest to us and we have anecdotal evidence that, for wine, it is best to start the machine around peak fermentation and continue its use until about 1.000 specific gravity. Shorter periods of use, starting just prior to peak and continuing for 2-4 days during active fermentation, also have proven beneficial. We are always trialing how to better use the AromaLoc™ 5000 to produce the best finished product.

Using current practice, all the stripped aromas and alcohols exit the fermenter to the environment. This can be a problem and it has led to legislation in California to limit this source of pollution as it contributes to photochemical smog. AromaLoc™ 5000 recycles organic chemicals (aroma) back to the headspace to increase aroma in the wine which also limits aromatic chemical pollution. If you currently collect fermentation CO2 the product will be cleaner than you currently obtain due to the lower levels of organic contamination, using AromaLoc™. Read Wine Spectator article.

The Evidence

Trials to this point have been done at several boutique wineries in British Columbia’s Okanagan wine region and an ultra-premium USA winery. Small volume systems have been tested by home wine and beer enthusiasts as well as U-Brew facilities. We learned a lot pioneering this product’s development; based on blind tastings with industry qualified professionals and hobbyists, and on GC/MS analyses, we have fine-tuned the AromaLocTM system to be scalable from 20L to virtually any size.

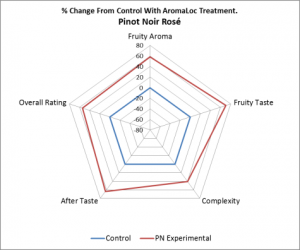

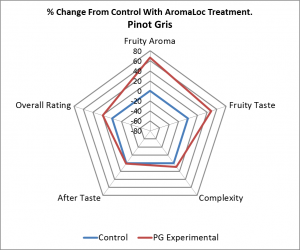

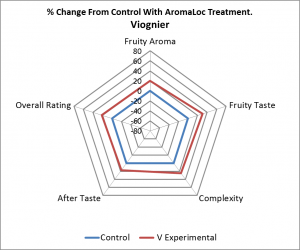

We realize this sounds “almost too good to be true” but this is not the case. During seven years of research and development we have conducted dozens of fermentation trials. In all AromaLoc™ trials the juice is inoculated with yeast and well mixed before filling the control and AromaLoc™ trial fermenters. The results are blind tasted by industry professionals using both the control and AromaLoc™-treated products. Examples of recent tasting results on wine are shown below.

The blue lines are control and red lines AromaLoc™ treated. We are regularly getting at least 20% increases in rating categories and as can be seen the increased aroma affects different characteristics of the beverage also.

For more evidence please visit our Research and Development page.